|

Current News |

|

Chemistry A to Z |

|

About Internetchemistry |

|

- Imprint |

|

|

Electrospray droplet research yields surprising, practical results |

|

The technique of using small droplets created by subjecting liquids to electric fields is vital for a variety of applications, from a type of industrial painting called electrospraying, to a method for analyzing molecules in analytical chemistry, to manufacturing tiny micro- and nanoparticles for research and industry. "Despite its importance, industry doesn't really understand exactly how the drops form," said Osman Basaran, the Reilly Professor of Fluid Mechanics in Purdue's School of Chemical Engineering. |

|

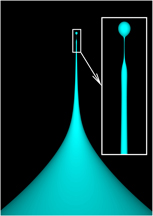

New findings showed that a liquid's viscosity plays a vital role in drop formation and size, a discovery that contradicts conventional wisdom, Basaran said. The researchers first created simulations to describe droplet formation mathematically, and then they performed experiments to support the computational work. "Computational simulations are now making it possible to understand such phenomena," he said. "But you always want to back up simulations with experimental data if at all possible." The findings are detailed in a paper appeared in the January 2008 issue of Nature Physics. The paper was written by doctoral student Robert T. Collins, undergraduate student Jeremy J. Jones, professor Michael T. Harris, and Basaran, all in the School of Chemical Engineering. Researchers have known for decades that applying an electric field to liquid drops causes the formation of structures that have a perfect cone at the leading edge. "Each drop takes on the shape of a chocolate kiss," Basaran said. Then, a thin ribbonlike strand of fluid is emitted from the leading edge of the droplet and breaks up into smaller droplets. "This was discovered about a century ago," Basaran said. "Nobody could really show precisely how it happened, but technologically it became very important." The method could make possible future technologies for creating flexible electronic circuits and solar cells by spraying material in ultra-thin layers. "Making small drops and controlling drop size is a big deal, and there are many techniques that people are working on to be able to model these computationally or theoretically," Basaran said. "There are many applications that would benefit by knowing the drop size. You cannot predict the drop sizes unless you have simulations to tell you how the strand is going to develop and break up into little droplets." The same phenomenon occurs in rain clouds. As rain droplets pick up an electrical charge, they take on an elongated football shape. Thin strands form at each end of the football, and those strands, in turn, form small droplets. "Again, the ends shoot these little strands or jets, which break up into drops," Basaran said. "And this has been suspected for a century to play a major role in how thunderstorms work." Understanding how the drops form is difficult because the strands are many times thinner than the original liquid from which they formed, which makes the mathematics especially challenging. "Others had not solved these equations in their full form before because they are very difficult, and we have now solved them without any approximations," Basaran said. Conventional modeling methods use "diffuse interface" techniques, which do not precisely predict how the strands and droplets form, he said. The Purdue researchers used a more precise method called finite elements with elliptic mesh generation. The technique breaks down a material into many small segments and solves the mathematical equations governing the behavior of each segment separately. Using the method enables researchers to understand the dynamic, changing shapes of each segment making up the drop-forming strands and the droplets. The technique allowed the engineers to negotiate the dramatic size differences between the strands and original liquid, a process that falls in the realm of "multi-scale modeling." "Our approach allowed us to do this multi-scale modeling in one big calculation," Basaran said. In the experiments, an electric voltage was applied to a small metal rod positioned about an inch from a puddle of liquid. The liquid was pulled toward the tip of the rod and took on a conical appearance. Strands of liquid, which subsequently broke into droplets, were then emitted from the liquid cone. The Purdue researchers conducted experiments using liquids with large viscosities, including those similar to fuels, whereas past research has concentrated on lower viscosity fluids like water. "This may prove to be important in combustion applications because fuel is sprayed into engine cylinders using fuel injectors," Basaran said. "We studied higher viscosity fluids to see the effect of viscosity, which other people had never seen before. It turns out that the viscosity actually has a big effect on droplet size." Future research will continue to study how droplet formation is influenced by other characteristics of a liquid. These characteristics include the electrical conductivity of fluids and the surface tension, the latter being responsible for the beading of water droplets on a recently waxed car. "We are just scratching the surface because there is such a large range of viscosities and other characteristics of fluids that affect droplet formation and size," Basaran said. "There could be many surprises." The research has been funded by the U.S. Department of Energy. |

|

|

|

|

Related topics - search form: |

|

|